Applying a even coating to wood finishes can seem hard to DIYers new to using a spray gun. Whether you're finishing furniture, cabinets, trim, or any other wood project, following some basic techniques will help you get an even coat with each pass of the spray gun.

Choose the Right Spray Gun

There are three main types of spray guns to consider for wood finishing.

HVLP (high volume, low pressure) spray guns. These operate at a lower air pressure and higher fluid volume compared to conventional spray guns. The lower pressure results in less overspray and material waste, making HVLP spray guns a good choice for beginners learning spray finishing techniques. They allow excellent control during application.

Conventional spray guns. These operate at a higher air pressure (30-60 psi) and push the finishing material out at a high velocity. Conventional spray guns work well for painting large surfaces, but the increased air pressure makes them less ideal for detail work.

Airless spray guns. Airless sprayers use hydraulic pressure rather than compressed air to push the finishing material through the tip. This allows for high output with less overspray. Airless spray guns are a good choice for painting fences, decks, siding and other large exterior projects.

For most interior wood finishing work, an HVLP spray gun is the best option. Match the size of the gun's nozzle to the viscosity of the coating you'll be spraying. Lighter viscosity sealers and stains will require a smaller nozzle, while thicker lacquers and varnishes call for a larger nozzle.

Preparing the Wood Surface

Fill any holes, cracks and grain with wood filler and sand the entire surface smooth, progressing up through finer grit sandpaper like 150, 220 then 320. Before spraying, wipe away dust with a tack cloth. Moisten the surface slightly with water using a spray bottle for bare wood, or apply wood grain filler for an ultra-smooth surface.

Thinning and Straining the Material

Most wood finishes should be thinned according to the manufacturer's instructions before spraying for a smooth, consistent application. This improves the flow through the spray gun's nozzle. Typical thinning ratios are 1:1 or 2:1 thinner to finish.

After thinning, pour the finish through a paint strainer into the cup of a gravity-fed gun or the reservoir of a siphon gun. This removes any particles that could clog the spray nozzle.

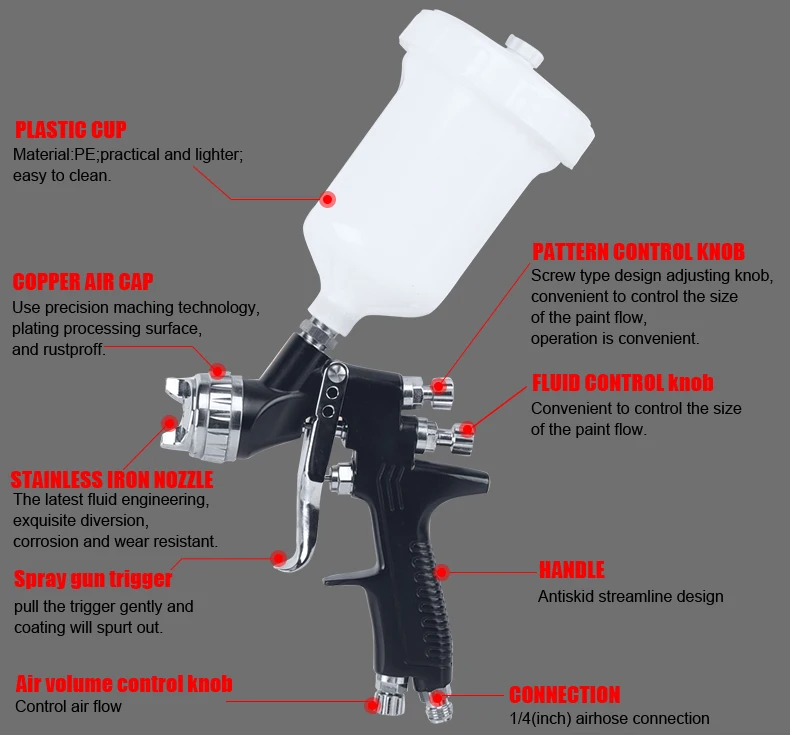

Adjust Spray Gun Settings

Air pressure for HVLP. 8-10 psi for thin liquids; 10-12 psi for thicker lacquers and paints.

Material flow. Turn needle adjustment knob to fully closed. Open slowly until you get desired fluid output.

Pattern shape. Adjust fan control valve until you achieve an even, oval pattern, wet in the middle.

Applying the Coating

When ready to spray, hold the gun perpendicular to the surface about 6-10 inches away. Apply a single, even coat using a side-to-side sweeping motion at a consistent speed. Move the spray gun parallel to the wood grain, overlapping each stroke by about 30 percent. Release the trigger at the end of each pass to avoid excess buildup. Avoid holding the spray gun closer or lingering in one area, which can cause drips and runs.

Maintain the same distance and speed across the entire surface for an even application. Horizontal surfaces can be coated more quickly by spraying the perimeter first, then filling in the middle area with parallel strokes. For vertical surfaces, spray from top to bottom.

On intricately shaped pieces, slowly rotate the object to reach all angles, spraying perpendicular to each surface. Round objects like table legs may require tilting the spray gun slightly to reach recessed areas.

DIYers and professionals alike can achieve flawless finishes with the AEROPRO A605 HVLP Spray Gun, a lightweight and versatile air spray gun perfect for applying stains, sealers, paints, and clear coats smoothly and evenly on wood, metal, plastic, and more.

S.S nozzle and needle,brass air cap, gun body can bear quadrupling working pressure. Paint utilization rate can reach 65%. Designed for comfort and control, the A605 features an ergonomic handle and adjustable trigger for easy maneuverability during long spray sessions.

Model No:A605

Standard Nozzle:φ1.3mm

Operating Pressure:2.4-3.0bar

Pattern Width:200-300mm

Air Consumption:5.5cfm

Paint Capacity:400cc

AEROPRO has quickly risen to become an unrivaled global producer of air-powered devices including air tools, air spray gun, air nailer, airless paint sprayer, and etc.

AEROPRO seeks independent sales agent to represent and market our industry-leading pneumatic tools. We support OEM, ODM, OBM customization, small order quantity is acceptable and samples are available.

Make any cooperation possible. Any services related to the product, inquire with us now! Sales@Aeroprotools.Com