If you're looking to paint your own car or motorcycle, having the right skills and techniques for using an automotive spray gun is vital.

Learning how to properly handle and adjust it will directly impact the quality of your paint jobs. We'll cover some key techniques for using an HVLP (high volume, low pressure) spray gun, the type commonly used for automotive refinishing.

Proper Gun Setup and Adjustments

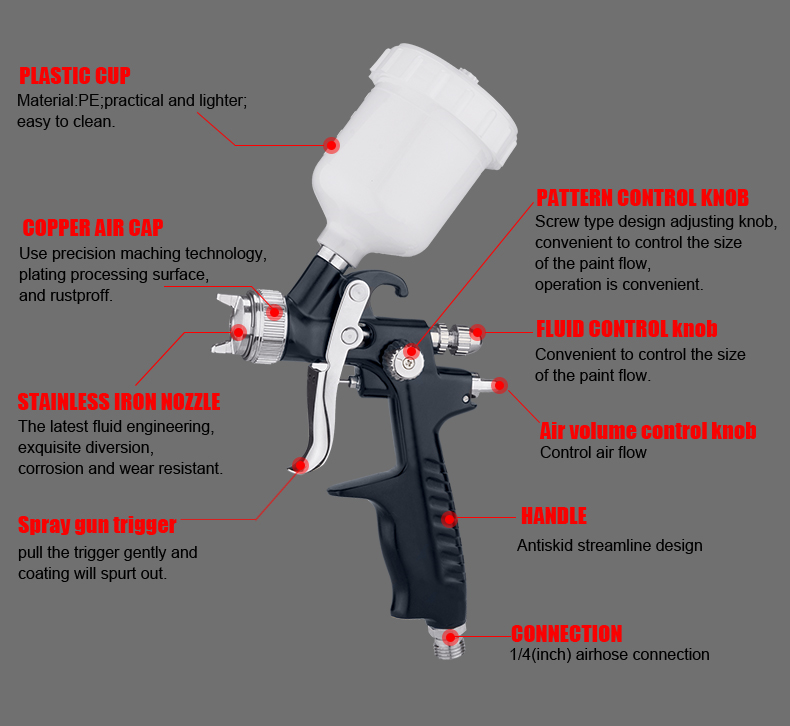

Before spraying, you need to ensure your gun is set up correctly. Screw the cup tightly to the gun body to prevent leaks. Attach the air hose with no kinks and set the pressure between 10-20 PSI for basecoat. Make sure the fluid knob is closed before you open the air valve. Test the fan pattern and adjust the pattern control knob so you get an even, oval-shaped spray about 8-12 inches wide. You want a soft, feathered edge, not a defined line at the edges.

The distance you hold the gun from the surface, called the gun distance, is also key. For basecoat, this is usually 6-8 inches. Clearcoat is applied closer, around 4-6 inches from the panel. Adjusting the fluid knob controls the amount of paint coming out. Turn it in gradually until you get a wet coat without any dry spraying. Proper setup gets you off to a good start before you spray.

Priming the Spray Gun

It's crucial to properly prime or prepare the gun before spraying. With the air and fluid knobs closed, pour your basecoat into the cup. Next open the fluid knob about 1/4 turn and spray into a garbage can or onto cardboard. Do this until any air pockets are eliminated and paint fully covers the tip of the nozzle. This ensures an even application of paint on your first pass.

When spraying clearcoat, don't prime the gun. Instead, use just 1 or 2 passes over scrap material to verify your pattern before applying the clear. This prevents film buildup on the nozzle which can cause defects.

Spraying Technique Basics

The key to great results with a spray gun is using proper technique. First, always spray perpendicular to the surface in straight, even passes. Arcing the gun or spraying at angles will deposit inconsistent paint thickness. Keep your strokes smooth with no hesitation at the start and stop of passes. Hesitating can cause drips.

Maintain your gun distance consistently throughout the pass, and overlap each stroke 50% to avoid dry edges. On large panels, use a crosshatch pattern – apply a full wet coat side to side, then layer another wet coat up and down over it. This ensures full coverage. When spraying complex three-dimensional areas like bumpers, regularly rotate around the piece so you hit it from all angles.

Tackling Different Surfaces

The technique might need to be adjusted based on the surface you're spraying. Large flat panels like car hoods allow straight passes, while complex curves or recessed areas take more maneuvering. When spraying doorjambs or bumper inserts, turn your wrist to follow the shape. Vertical panels often require spraying sideways to hit the surface perpendicular.

Plastics like bumpers require a lighter coat and holding the gun further back to prevent pooling. Primer needs a 50% overlap and fully wetting each pass for proper adhesion. Spray textured or porous surfaces like fiberglass slightly heavier to fill the grain. Mastering these small adjustments will ensure you learn to adapt your technique to any spray job.

Pair proper technique with quality AEROPRO A606 Top Grade HVLP Air Spray Gun, you'll be on your way to professional-looking automotive paint jobs.

Aluminum alloy gun body with anodic treatment surface, with precise machined air cap set. Air micrometer with graduations to adjust atomization air. Spray gun body designed with small dimensions and low weight for fatigue-free working. Single-handed flat control to adjust the spray pattern to the object which is to be painted.

Great for Automobile finish painting, best used for spray painting of middle or high adhesive for surface finishing and middle coating.

Model No:A606

Feed Type: Gravity

Standard of Nozzle: Φ1.0mm

Operating Pressure: 2.0bar

Pattern Width: 130mm

Paint Capacity: 100cc

Air Consumption: 2.8-.4.6cfm(79.6-130L/Min)

Air Inlet:1/4inch

AEROPRO has quickly risen to become an unrivaled global producer of air-powered devices including air tools, air spray gun, air nailer, airless paint sprayer, and etc.

AEROPRO seeks independent sales agent to represent and market our industry-leading pneumatic tools. We support OEM, ODM, OBM customization, small order quantity is acceptable and samples are available.

Make any cooperation possible. Any services related to the product, inquire with us now! Sales@Aeroprotools.Com