When it comes to auto body work and refinishing damaged areas on a vehicle, having the right tools for the job is essential. A high quality touch up spray gun allows auto body technicians to achieve professional paint results when doing small repairs and touch ups.

Understanding Touch Up Spray Guns

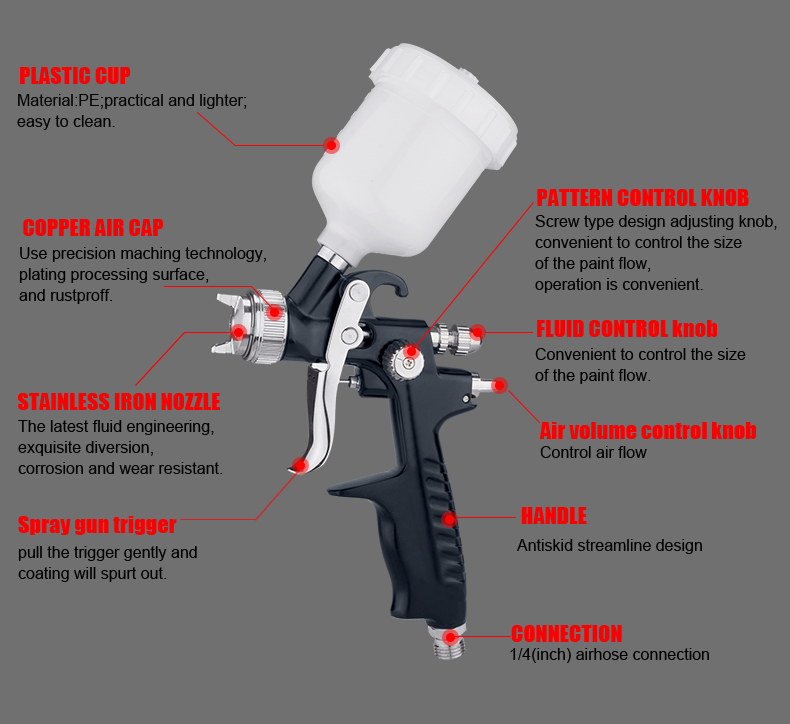

Touch up spray guns are small, lightweight spray guns designed for small painting jobs like auto refinishing. They have a compact size and fine spray pattern that gives you great control for detailing small areas. Touch up guns use less paint and atomize it into finer droplets than a full-size spray gun, allowing for a smoother finish.

They connect directly to a small paint cup, while not suitable for overall car painting, touch up guns excel at spot repairs, blending panels, and painting small parts like mirrors, emblems, and trim pieces. They are also handy for adding clearcoat to localized areas.

Why Touch Up Spray Guns Are Necessary

Touch up spray guns are a vital tool for auto refinishing because they allow painters to accurately apply paint only where it is needed, without affecting surrounding areas. For small repairs like stone chips, scratches, and spot rust, it would be incredibly difficult to match the original factory paint job using a full-size paint sprayer. The overspray would coat everything nearby and make blending the repair seamlessly almost impossible. Touch up guns provide focused spray patterns and fine control over paint flow that enables painters to coat only the damaged portion of a panel, this minimizes wasted paint and overspray.

For blending paint edges, the precision offered by a touch up gun gives painters the ability to softly fade and transition the new paint into the existing finish. Simply put, touch up spray guns make the difference between an obvious, splotchy repair and one that looks like it came straight from the factory. Their precise control and focused spray patterns are what make professional quality auto refinishing repairs possible.

Techniques Of Using a Touch Up Spray Gun

Air pressure impacts the spray pattern and how the paint atomizes. Too low, and the pattern will be thin and spitty. Too high, and paint spreads too wide while drying too fast. Install an inline regulator and gauge on your spray gun so you can accurately control pressure. Also, use a moisture trap to remove water from the line which can ruin paint.

Adjust pattern size as needed for what you're painting, the fan control knob at the rear of the spray gun adjusts the fan pattern width. For large flat areas, set it to full width. For tapered surfaces like car fenders, narrow the pattern so you can spray perpendicular to the changing surface contour. When spraying delicate edges or stripes, turn the knob to narrow the stream for pinpoint accuracy.

Having the right paint flow is critical. Too little and you'll have thin, uneven coverage. Too much and paint will run. The touch up spray gun has an adjustable screw near the trigger to control fluid output. Start with it turned in gently, then increase flow as needed. Generally, you want the lowest flow rate that still lays down an even coat. Testing on cardboard will dial-in the ideal setting, adjust in small increments for precise control.

For auto body technicians looking to upgrade their spray gun arsenal, AEROPRO A606 Pro Touch Up spray guns are definitely worth considering.

Spray gun body designed with small dimensions and low weight for fatigue-free working. Aluminum alloy gun body with anodic treatment surface. Single-handed flat control to adjust the spray pattern to the object which is to be painted. Stainless steel needle and nozzle accommodate a variety of coating. Air micrometer with graduations for adjusting atomized air.

Even better surface quality for spotless finish. Great for Automobile finish painting, with AEROPRO A606 Pro Touch Up spray gun in hand, painters can tackle any auto refinishing job with confidence.

Model No:A606

Feed Type: Gravity

Standard of Nozzle: Φ1.0mm

Operating Pressure: 2.0bar

Pattern Width: 130mm

Paint Capacity: 100cc

Air Consumption: 2.8-.4.6cfm(79.6-130L/Min)

AEROPRO has quickly risen to become an unrivaled global producer of air-powered devices including air tools, air spray gun, air nailer, airless paint sprayer, and etc.

AEROPRO seeks independent sales agent to represent and market our industry-leading pneumatic tools. We support OEM, ODM, OBM customization, small order quantity is acceptable and samples are available.

Make any cooperation possible. Any services related to the product, inquire with us now! Sales@Aeroprotools.Com