By simply swapping out the abrasive media and adjusting air pressure levels, sandblasting guns can handle a range of applications across various materials and industries.

What is a Sandblasting Gun?

Let's quickly cover the basics of sandblasting. Sandblasting, is a process where small particles (typically sand, but other abrasive media can be used) are propelled at high speeds towards a surface.

The key components of a sandblasting system are the abrasive media, an air compressor to provide propelling force, a pressurized vessel to hold the media, a delivery hose, and the sandblasting gun itself. The gun connects to the hose and air supply and allows the user to accurately direct the media stream.

Understanding Abrasive Media

The performance and results achieved with a gravity feed sandblasting gun are largely dependent on the type of abrasive media used. Different materials are suited for different applications, choosing the right abrasive media is important for achieving the desired surface finish and limit damage to the substrate.

Sand

Once the most widely used abrasive, sand has largely been replaced by safer and more efficient alternatives due to its potential health hazards. However, it is still used in certain applications where its affordability outweighs its drawbacks.

Aluminum Oxide

Aluminum oxide, also known as alumina, is a popular choice for sandblasting due to its hardness and angular particle shape, which makes it highly effective in removing coatings and contaminants. It is available in various grit sizes to suit different applications.

Silicon Carbide

Silicon carbide is another highly abrasive media that excels in aggressive surface preparation tasks. Its sharp, angular particles make it particularly effective for removing tough coatings, rust, and other stubborn contaminants.

Glass Beads

For applications that require a gentler touch, glass beads are an excellent choice. Their spherical shape and relatively soft composition make them ideal for cleaning and polishing without causing excessive damage to the underlying surface.

Plastic Media

Plastic abrasive media, such as those made from polyester or acrylic, are becoming increasingly popular due to their environmental friendliness and reduced risk of contamination. They are often used in applications where cleanliness and minimizing dust are priorities.

Surface Preparation Applications

So what are some of the key applications where sandblasting guns are utilized? These powerful tools play an essential role in surface preparation across numerous industries.

Rust/Paint/Coating Removal

One of the most common uses of sandblasting is to strip away rust, old paint, grease and coatings from metal surfaces during preparation for re-coating or finishing. The high-energy abrasive stream efficiently removes surface contaminants, creating an ideal anchor profile for new coatings and treatments. Ship hulls, bridges, industrial equipment, automobile bodies and more rely on sandblasting for these preparation processes.

Etching and Finishing

Conversely, sandblasting can also be used to impart precise surface finishes and textures to materials like metal, glass, stone and plastics. Matte finishes, decorative effects and brand logos are easily created using sandblasting's controlled abrasive stream. Award trophies, signage and furniture are just a few examples benefiting from this technique.

Deburring and Cleaning

The precision of sandblasting makes it ideal for knocking down burrs, shavings and excess material in manufacturing processes like injection molding, die casting, stamping and more. It provides an efficient alternative to manual grinding and deburring. Sandblasting also excels at dislodging caked-on residues like carbon buildup, concrete slurry or factory grime from industrial equipment during rebuilds and maintenance events.

Increasing Traction and Grip

Sometimes you need to reduce rather than increase surface roughness and friction. Golf clubs, skateboard ramps and similar products often use mild sandblasting to add a degree of slip resistance. The process slightly roughs up these surfaces just enough to improve traction without being abrasive.

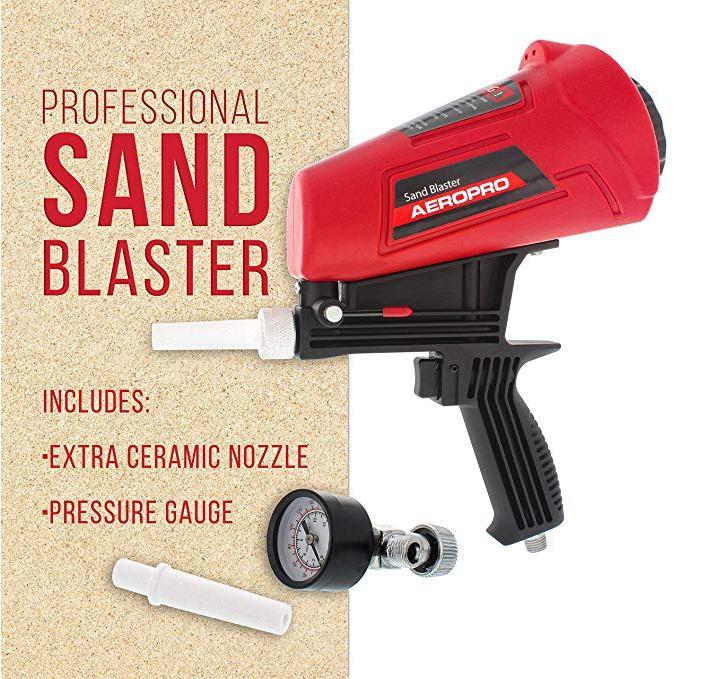

By considering the specific application, materials being blasted, levels of portability needed, and budget, AEROPRO V641 gravity feed Sandblasting Gun provide an portable and simple option.

The replaceable nozzle allows for customizing the blast pattern, The integrated hopper allows for a continuous flow of abrasive media. It offers control and versatility, operators to tackle a wide range of surface preparation tasks with precision.

The V641 is rated for use with most common blast media types like aluminum oxide, silicon carbide, glass beads, walnut shells, baking soda and more.

Container Capacity : 900ml(30Oz).

Operating Pressure : 60 -100 PSI

Working Pressure : 70 -100 PSI

Air Consumption : 10 CFM – 100 PSI

Suggested Air Compressor : 3 HP

Fitting Size : 1/4″ NPT

Gun Material : ABS

Packaging Weight : 1.25 lbs

Max. Particle Size : 14 Grit

AEROPRO has quickly risen to become an unrivaled global producer of air-powered devices including air tools, air spray gun, air nailer, airless paint sprayer, and etc.

AEROPRO seeks independent sales agent to represent and market our industry-leading pneumatic tools. We support OEM, ODM, OBM customization, small order quantity is acceptable and samples are available.

Make any cooperation possible. Any services related to the product, inquire with us now! Sales@Aeroprotools.Com